2024

Want to Expand Your Operations, but Not Your Warehouse

If you’re facing sudden expansion at your warehouse – and tripping over inventory that’s starting to spill off shelving and into the aisles – it may be time to consider storage automation technology.

With space at a premium for facilities, operations managers are searching to ways to maximize floor space and optimize storage capacity. So which one should you focus on – floor space or capacity? Oh, both? Everyone says that. Don’t worry, you can have your cake and eat it too – let me tell you about some technologies that can help.

Maximizing Floor Space

When we talk about floor space, we’re talking square feet – so width x depth. Easy right? Now consider how much floor space you’re occupying with product or equipment. How about your aisle spacing – can you reduce the amount of floor space used or is it narrow enough already? Don’t forget about your vertical space. This area is commonly underutilized. If you have available space above your shelving you could benefit from a space evaluation to determine how to better use this area to match your business needs.

Optimizing Capacity

Capacity, by definition, is the maximum amount something can hold or contain. It’s simple math really – height x width x depth = cubic feet, which equals capacity. Take a look at your shelving – are they evenly spaced leaving wasted room at the top of your products? This is extra capacity you aren’t taking advantage of. Consider re-slotting your storage areas to get rid of any “air space” to aim for the tightest storage possible while still making product accessible.

Some Technologies that Can Help

For facilities relying on traditional shelving for non-palletized items these tips and tricks are only going to get you so far. To support rapid growth you’re going to need to make a technology change or expand your building. In this case, consider automated storage and retrieval equipment. Why make the investment you ask? These self-contained systems offer higher density storage in a more compact footprint than manual equipment can provide and the ROI is typically under 18 months. Three primary types:

- Horizontal Carousels – Consist of a fixed number of bins mechanically linked to an overhead or floor mounted drive track to form a complete loop. The oval track rotates horizontally to deliver storage locations to an operator at a picking location automatically. These automated storage and retrieval systems eliminate unproductive travel and search time by delivering the product to an operator.

- Vertical Carousels – Comprised of a series of shelves that rotate around a track—similar to a Ferris wheel—these automated storage and retrieval systems deliver stored items safely and quickly to an ergonomically positioned work counter at the operator’s command, eliminating walk and item search time.

- Vertical Lift Modules (VLMs) – An enclosed automated storage and retrieval system that consists of two columns of trays with an inserter/extractor in the center. The inserter/extractor automatically locates and retrieves stored trays from both columns and presents them to the operator at a waist-high pick window, eliminating travel and SKU search time.

Now each type of system offers different benefits when compared to your traditional shelving, all of which reduce the space and footprint required, therefore eliminating the need for an expansion. These space efficiencies can be further leveraged either through the storage of more products in the same amount of facility footprint, or via an expansion in the number of SKUs stored.

Increased Capacity

One way to compare automated storage and retrieval technologies to shelving is based on the available capacity within each system. A capacity comparison reveals how many sections of shelving fit into an automated storage machine, quantifying storage density within the unit.

Integrating an automated storage and retrieval system into your process allows you to densely store product on a shelf, tray or carrier. Storing items comparable in height together maximizes the cube and ensures you’re getting the most of out the units overall capacity.

The Shuttle XP for example stores trays on 1” increments. The densely compacts all trays as close together as possible based on product height. Storage locations for each tray can be a predetermined position or the storage location can change every time the tray is brought back into the unit to ensure maximum storage density within the machine. You will never have to think about re-slotting – just store “like height” items on the same tray and the slotting is done for you.

Recovered Floor Space

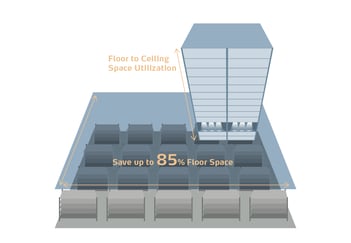

Another way to compare these technologies is based on floor space, measured in square feet. As a general rule of thumb, when compared to standard shelving, horizontal carousels save up to 60 percent of floor space, vertical carousels save up to 75 percent of floor space and VLMs save up to 85 percent of floor space. Combining these figures with an 18 month ROI will stop any building expansion plans dead in its tracks.

Look up! A lot of people don’t realize they can utilize the vertical height in their warehouse or distribution center without needing a 20’ tall ladder to access the top shelf. VLMs utilize the floor to ceiling height ranging from 10’ tall to 90’ if you really wanted a monster of a machine! This recovered floor space allows you to reallocate the space to another department in the facility or expand with another product line.

It just requires some research and a bit of math to determine which automated technology is best for you. We have Sales Engineers on calls to discuss all the options with you.